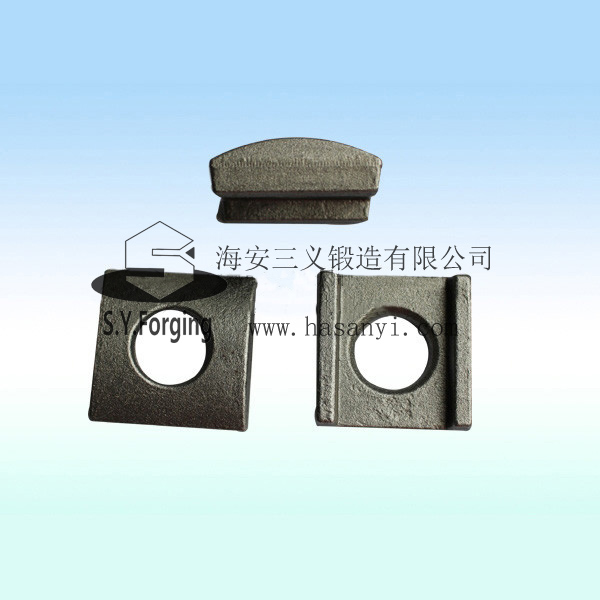

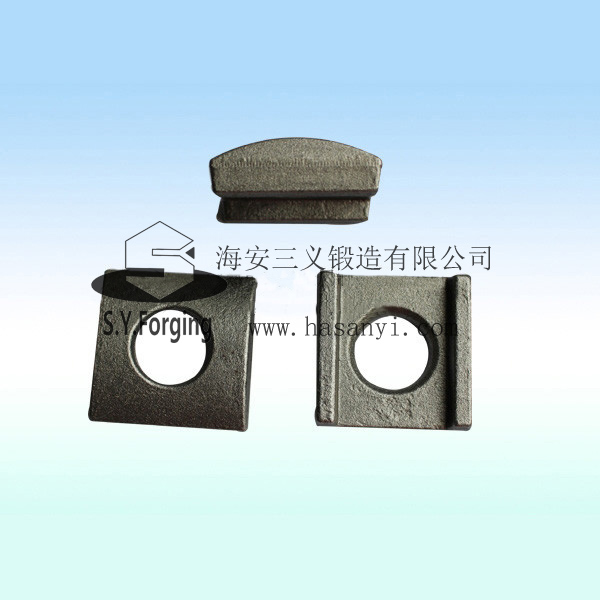

| Forging railway pressing plate Haian Sanyi |

| ¡¡Hits£º1631¡¡AddTime£º2020/5/4 10:49:56 |

Forging railway pressing plate Haian Sanyi Haian Sanyi Forging Co., Ltd. is an enterprise mainly engaged in precision forging, specializing in the production of forging parts for various railway fastening plates, mining machinery, bridges, electric power, highways, railways, ships and other industries.

The utility model can effectively reduce the friction between the screw rod and the base in the process of rotation, and avoid the wear of the external surface of the screw rod caused by long-term use. Through the setting of the turntable, it is convenient for the staff to rotate the screw rod and operate it. Through the setting of the slide rail and the slide block, it can effectively increase the stability of the screw ring in the process of movement, so as to avoid the screw ring from skewing, resulting in seizure. In the figure: foundation; base; track; fixed block; pad body; fixed seat; cavity; bearing II; turntable; threaded rod; through hole; fixed rod; limit block; slider; slide; pusher; screw ring; limit rod; limit hole; bearing I. The technical scheme in the embodiment of the utility model will be described clearly and completely in combination with the drawings in the embodiment of the utility model. Obviously, the described embodiment is only a part of the embodiment of the utility model. Not all embodiments. Based on the embodiments in the utility model, all other embodiments belong to the protection scope of the utility model.

The screw rod 18 can be driven to rotate by the rotation of the worm 16, which has the advantage of convenient use. The inner bottom wall of each cavity 7 is provided with a sliding groove 15, and the sliding block 14 is clamped in the sliding groove 15, and the sliding block 14 can be used to move in the sliding groove 15 to limit the angle of the threaded pipe 13, so as to ensure the stable movement of the threaded pipe 13. The front side of the rail fixer body 3 is fixedly inlaid with a second bearing 4, the inner ring of the second bearing 4 is fixedly connected with a rotating shaft 5, and the front side of the rotating shaft 5 is fixedly connected with a rocker 6, which can pass through The rotation of the rocker 6 drives the shaft 5 to provide power for the installation. The back of the shaft 5 is fixedly connected with the worm 17, and the worm 17 is meshed with the worm 16. The rocker 6 drives the worm 17 to rotate, thus driving the worm 16 to rotate. The utility model has the advantages of convenient operation. The stick 11 is cylindrical, and the diameter value of the stick 11 is smaller than the diameter value of the socket 10. When using, the clamp block 1 is clamped into the clamp In the groove 9, the rail 2 is limited and fixed by the top end of the clamp 1.

Rail pressing plate is a kind of fitting used to press and fix the rail and I-beam or concrete beam or ground. It is generally fastened with hexagon bolt or embedded bolt. Rail pressing plate is also called (driving pressing plate, crown block pressing plate, track pressing plate, lifting rail pressing plate). Rail pressing plate can be divided into: gdgl pressing plate is also called 514 double hole pressing plate (pressing plate for I-shaped steel beam). DGL pressing plate is also called long hole casting pressing plate (pressing plate for concrete beam and concrete floor). The model of gdgl pressing plate can be divided into gdgl-1 (for 38kg rail) - gdgl-7 (for 120kg rail). The model of DGL pressing plate can be divided into 6a-1 (for 24kg rail) - 6a-7 (for 120kg rail).

Make the sliding plate 2 and the side pulley 3 close to the track, and place the supporting wheel 14 on the upper part of the track, so that the device can be stably placed on the track, and slide through the side of the track and the top of the track, so that the device is more stable, not used for ground contact, so that the crack detector 16 is always located directly above the track, and install the plate sliding plate side pulley supporting wheel sliding plate slide groove folding plate 1 on the torsion spring shaft Under the action of 1 and folded plate axis 13, the device can move various types of tracks, so that it can be applied to the detection of various tracks. 16. Under the action of extension axis 19 and steering axis 20, the push rod 7 is adjusted to the comfortable angle of the staff. The staff can drag the device along the track through handle 8, thus recording the data to complete the detection, saving time and operation Simple. The utility model discloses a railway track support plate, which relates to the technical field of railway track, including a support plate body. The upper surface of the support plate body is provided with two groups of relative sliding grooves.

The rail is fixed on the sleeper, and the ballast is under the sleeper, which is fastened by rail support, fastener, rail ballast, track clamp plate, elastic strip, rail spike and other railway accessories. Because of the influence of environmental factors, there will be different degrees of settlement in the use of railway track. In the existing technology, most of the railway workers carry electronic level to measure the road and rail point by point. In this way, the railway workers need to carry electronic level at any time to increase the labor intensity of the railway workers, and the angle after the rail settlement cannot be detected. The utility model aims to provide a railway track settlement detection device, which has the advantages of low labor intensity of railway workers and simultaneous detection of the rail settlement distance and angle. To achieve the above purpose, the utility model is realized by the following technical scheme: a railway track settlement detection device, which includes two support mechanisms, both of which include a support box.

|

| ¡¾Refresh¡¿¡¾Favorites¡¿¡¾Print¡¿ ¡¾Close¡¿ |

| Previous:Production technology of pressing plate for Sanyi railway in Hai'an¡¡Next:What is the technology of producing non-standard bolt and nut? |

HAIAN SANYI FORGING CO.,LTD

MOBILE:18936109298

CONTACT£ºMR CHA

TEL:0513-88600106

FAX:0513-88600108

E-mial£ºsales01@hasanyi.com

Address£º189 Renmin East Road, Qutang Town, Hai'an City

Website£ºwww.hasanyi.com